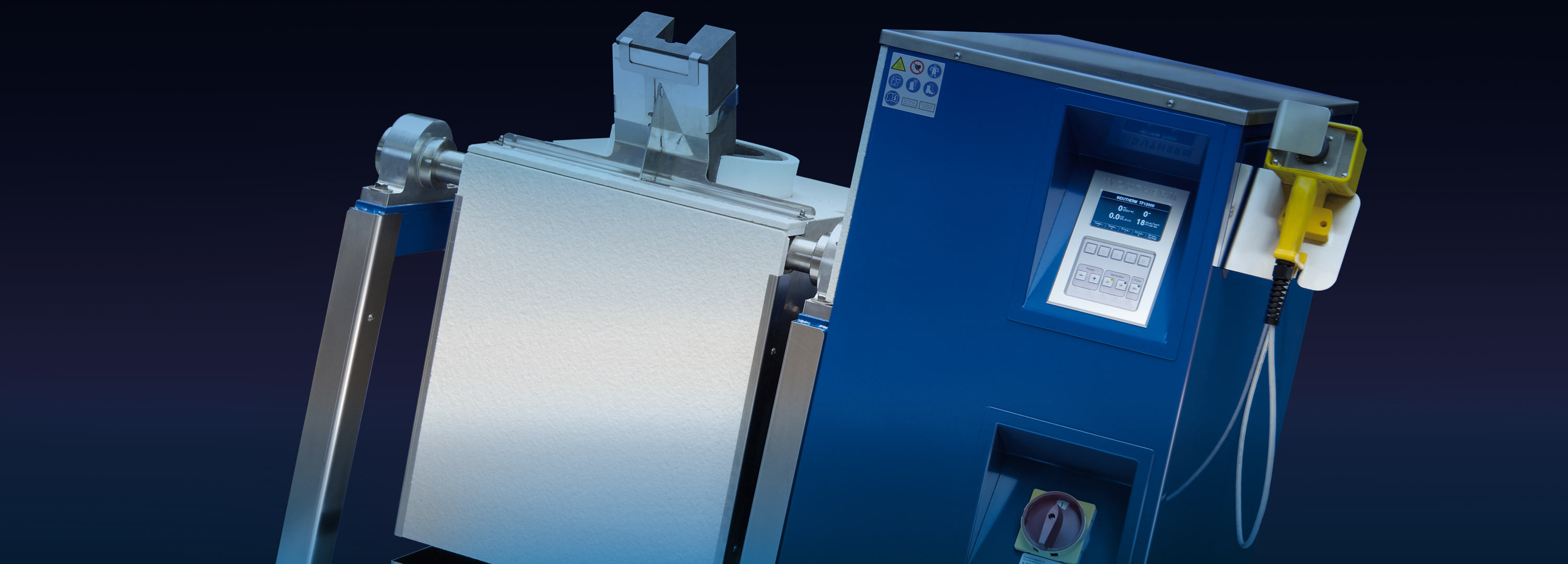

The cost-effective tilting furnace TF-6000

The „small“ TF machines have been developed with the focus on least possible energy consumption and on safe and ergonomic handling. The melting unit and crucible can be tilted and locked in position by the user at multiple angles for gentler filling. Such “soft pouring” also prevents damage to the crucible. Pouring off is continuous and gradual, using a pivot lever. The operator is forced to stand to the side of the machine – away from the dangers of the pouring area. In the rare event of a crucible breaking, the machine is not damaged – all of the assemblies are covered by a separate protective housing, and every model has a large collecting tray under the smelting unit to prevent potential loss of metal.

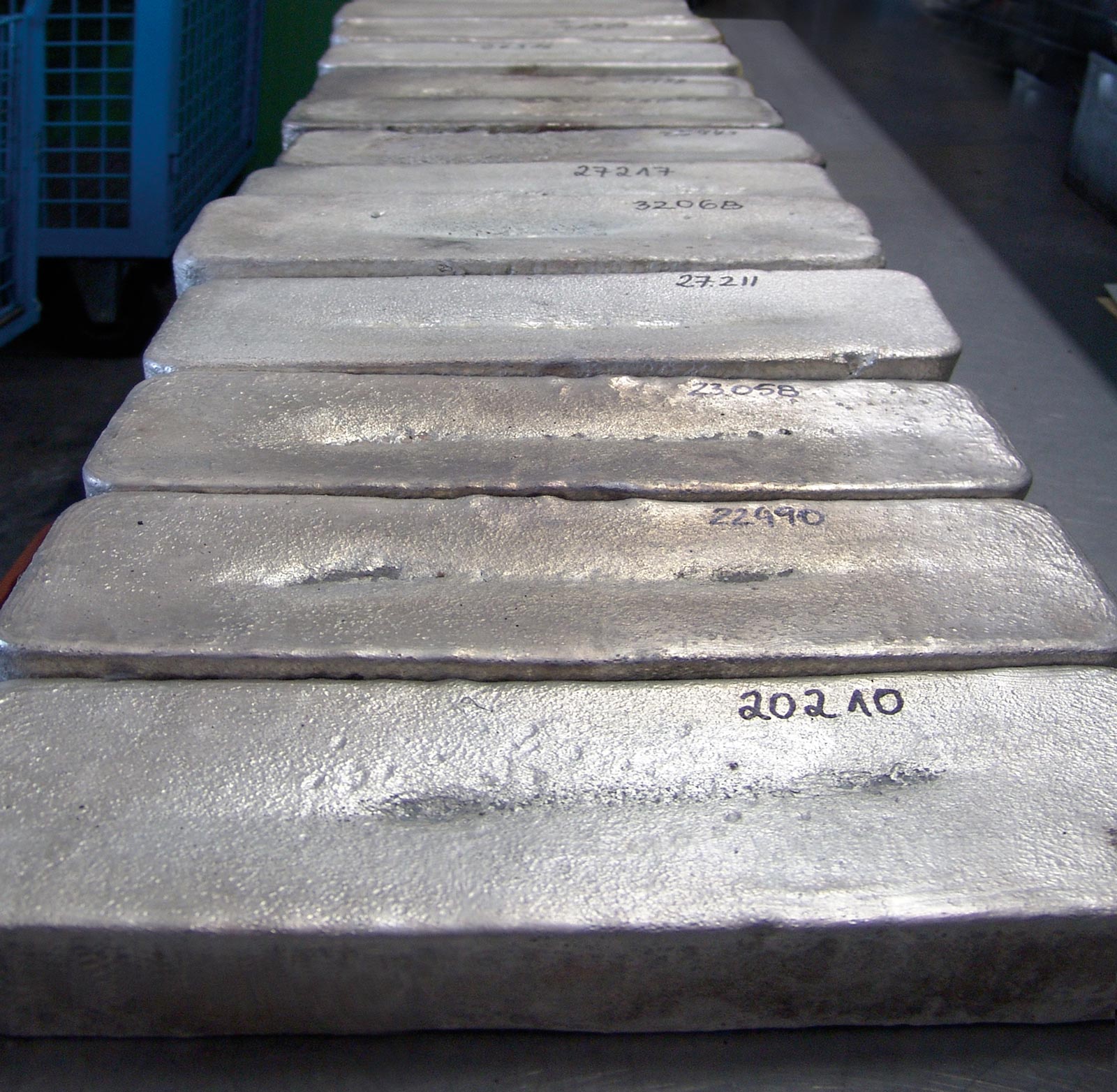

The TF 2000 and TF 4000 models, which like their predecessors are used both in the jewelery industry and in refineries, are completely new developments. They are equipped with new high-performance induction generators, which ensure that the melting temperature is reached much faster and ensure that the melt is thoroughly mixed and homogenized. Depending on the model, the capacity ranges from 2,000 ccm to 4,000 ccm crucible volume, which corresponds to approx. 60 kg gold 18.

Data Overview of TF-6000

■ standard equipment, ○ optional, - not available| TF-2000 | TF-Series | TF-4000 | TF-4000 HTC | TF-6000 | TF-Series | TF-12000 | TF-12000 HTC | TF-28000 | |

| Temperature max. | 1500° C | 1850° C | 1500° C | 1850° C | 1500° C | 1850° C | 1500° C | 1850° C | 1500° C |

| Power max. / electrical connection | 20 kW (3x400 V) | 20 kW (3x400 V) | 30 kW (3x400 V) | 30 kW (3x400 V) | 40 kW (3x400 V) | 40 kW (3x400 V) | 40 kW (3x400 V) | 60 kW (3x400 V) | 60 kW (3x400 V) |

| Control system | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout | by LCD-display, full text readout |

| Programs | 20 | 20 | 20 | 20 | 100 | 100 | 100 | 100 | 100 |

| Tilting by lever | ■ | ■ | ■ | ■ | - | - | - | - | - |

| Tilting with motor drive (remote control) | - | - | - | - | ■ | ■ | ■ | ■ | ■ |

| Temp. measurement by thermocouple | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ |

| Temperature measurement equipped with an optical pyrometer | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| RS 232, Ethernet, USB interface, diagnostic system | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ |

| GSM-modem for remote service | ○ | ○ | ○ | ○ | ■ | ■ | ■ | ■ | ■ |

|

DMS

|

■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ |

| InduthermCloud | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| iThermControl | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Protective gas flush to avoid oxidation | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Vacuum pump | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Moveable table (with customized molds) | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Hood for smoke vent | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

*real capacity for casting / useful volume