1 or 2 Stage Air Classifier systems for the precise separation of metal powders

The AC series Air Classifiers are designed for the precise separation of metal powders into fine and coarse powder fractions especially in the range < 25 µm, where conventional sieving operations fail.

For processing of small to medium size powder batches

Due to the Easy-to-Clean concept our Air Classifiers are ideally suited for any production with the need for frequent alloy or desired particle size changes, and especially for precious and other specialty metals.

These characteristics qualify the AC series machines for applications in research and development and also for large systems with a throughput of up to 200 kg / h (bronze or steel) and with double stage classification.

Classification under protective gas atmosphere: the G versions AC 1000 G / 3000 G

We particularly recommend the AC G-series for the separation of metals or alloys where the uptake of oxygen, moisture, or contamination from the room air must be avoided. An oxygen measuring system controls the process according to the set values. For example, a defined target O2 value can be programmed for the process start. For the classification of reactive metals, please contact us for more information

Data Overview of AC 1000

■ standard equipment, ○ optional, - not available

Find out more about AC 1000

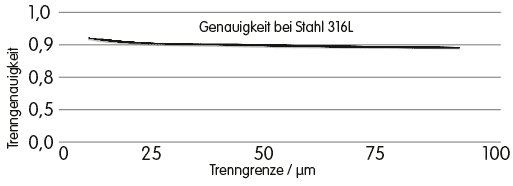

Cut point and separation precision

The cut point can be shifted by vaying the classifier wheel speed and the fan settings over a wide range while maintaining a very high separation precision.

Particle size distributio

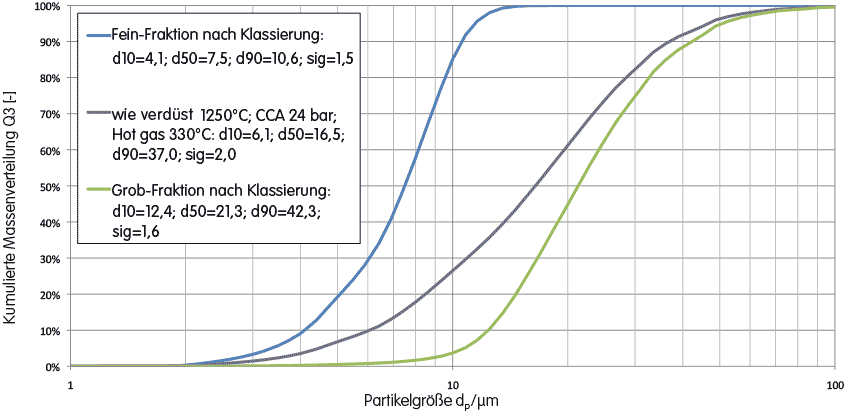

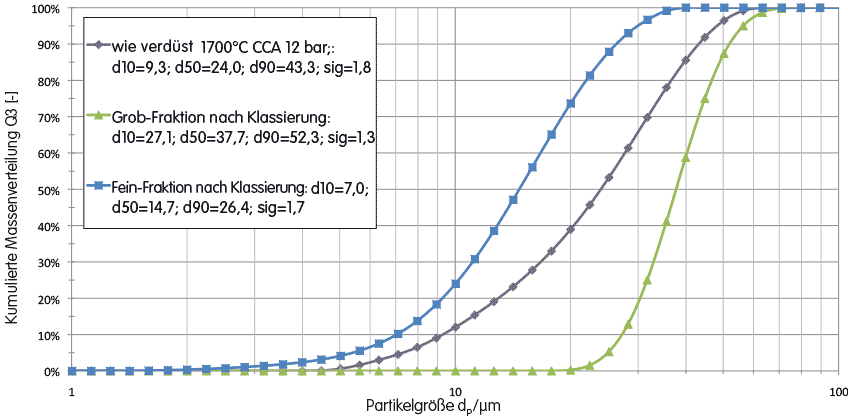

The following examples show a cut point at ~10 µm for 18ct gold powder and at ~25 µm for steel powder.

Particle size distribution of gas-atomized 18ct gold powder separated into coarse and fine powder fractions with the AC 1000 Air Classifier. Cut point in this example ~10 µm.

Particle size distribution of gas-atomized steel powder separated into coarse and fine powder fractions with the AC 1000 Air Classifier. Cut point in this example ~25 µm.